Projects

New Technology - In-field repair of composite structures.

The adoption of composites have taken a huge leap with not one but two application processes! We have developed two ways for in-field repairs to assets such as a Advanced Modular Composite Bridge (AMCB). Find out more here.

U.S.S. Ticonderoga - CG 47 Class, Aluminum Repair

The aging deck house on the ship class is constructed of 5456 T116 aluminum. The aging process results in material sensitization leading to stress corrosion cracking without warning. Weld repairs often reached $M however the repairs with composite patches were a successful alternative at a fraction of the cost.

Prototype Work on Aircraft Parts

This project consisted of developing a air cooling plenum due to the reports of engine overheating with this particular aircraft. To achieve the performance goals of the design the cowl needed modification to have the inlets match those of the plenum.

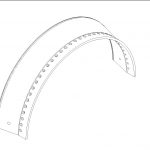

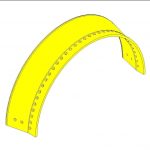

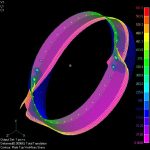

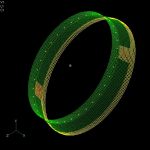

CVN Class Composite Running Gear Fairings

The running gear fairings on US Navy combatants are metallic and welded to the propulsion shafting bearing struts. As the Fleet moved towards 12 year dry dock intervals led to the need for pierside ship hull husbandry. The design and development of the bolted composite fairings made it possible for divers to perform maintenance on sacrificial zincs and stave bearings.

Jim Wilson's RV-8 Wingtip Repair

Jim was taxiing between hangars at KAND the day before the Race to the Sun 2015 and hit a guy wire. We repaired with a double, inside & outside, vacuum bag, cured with quick build oven and reinstalled on the aircraft in one day.

Beechcraft M35 Bonanza Overhead Console

The aircraft was scheduled for a new interior make over at Air Mod, Batavia, OH. The original OH consoles were vacuum formed plastic and in unrepairable shape. The customer wanted to replicate the parts in carbon fiber to offset a first class interior set with gray fabrics. Minor changes were made from the original factory configuration to allow for larger and more efficient eye ball vents. Part was fabricated with a vacuum assisted resin infusion process.

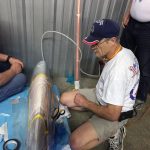

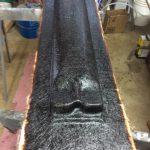

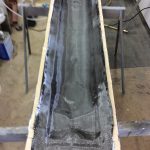

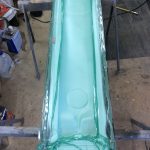

Bryan Patterson's Glasair SH-2TD Wing Repair

While being marshaled in to the Sun N Fun 2019 flight line the aircraft strikes a golf cart with the R.H. leading edge of the main wing; outside of the fuel cell and ahead of the spar. The wing laminate pedigree is 3 plies Style 7781 glass/Clark Foam/3 plies of 7781 with Derakane 470 vinyl ester. A 7781 fiberglass inner skin was splashed off of the leading edge outside of the damage area and while still green was trimmed, rolled up, inserted inside and bonded in place. Once cured, PVC foam was bonded to the inner skin top and bottom. The foam was sanded to the proper thickness and the surrounding structure was sanded to a 22:1 scarf taper. Two plies of E-TLX-1900 glass was laminated to the leading edge and three plies of 7725 of increasing size are laminated over the entire area. Peel ply, P3 film and a polyester breather is placed over the patch prior to applying vacuum. The cured patched is sanded and faired with dry micro mixture.